Servo System Retrofitting

Introducing an energy-saving system for older injection moulding machines involves upgrading the outdated electrical motor system with a new servo system. This implementation allows users to achieve up to a 60% reduction in electricity consumption. Injection moulding machines not only become more economical but also gain enhanced attractiveness and user-friendliness with the integration of PLC control alongside the servo system.

We specialize in retrofitting standard servo systems onto pre-owned injection moulding machines, transforming them into valuable assets for our customers. The advantages of this retrofitting process include:

1. Renovation, resulting in a precise, contemporary, and noiseless machine.

2. Power savings of up to 60% on renovated machines.

3. A one-year warranty is provided for the proper functioning of PLC, servo systems, and hydraulics.

4. Industrial-grade paint quality ensures that the machine looks like new.

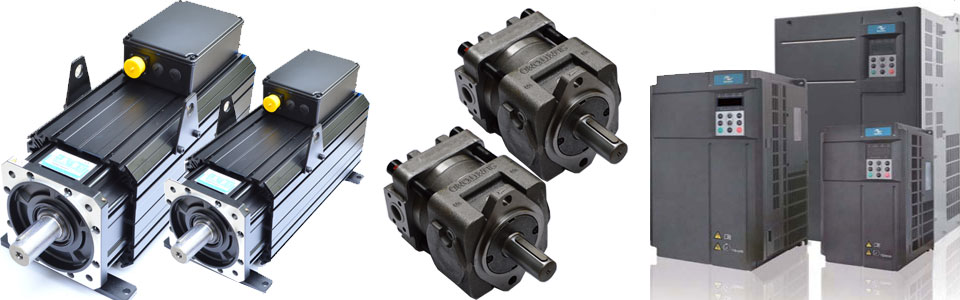

Servo Motor

A servo motor ensures accurate control of angular or linear position, velocity, and acceleration by functioning on the principles of a closed-loop system. Possessing the capability to deliver substantial torque at elevated speeds, servo motors prove highly effective in dynamic applications.

Servo Drive

A servo drive collaborates with a feedback system, commonly incorporating sensors like encoders or resolvers, to accurately control the motor’s position, speed, and torque.

Servo Pump

Servo pump system combines electronic control, servo valves, and variable displacement pumps to achieve accurate and dynamic control of hydraulic fluid flow and pressure in response to input signals and feedback.