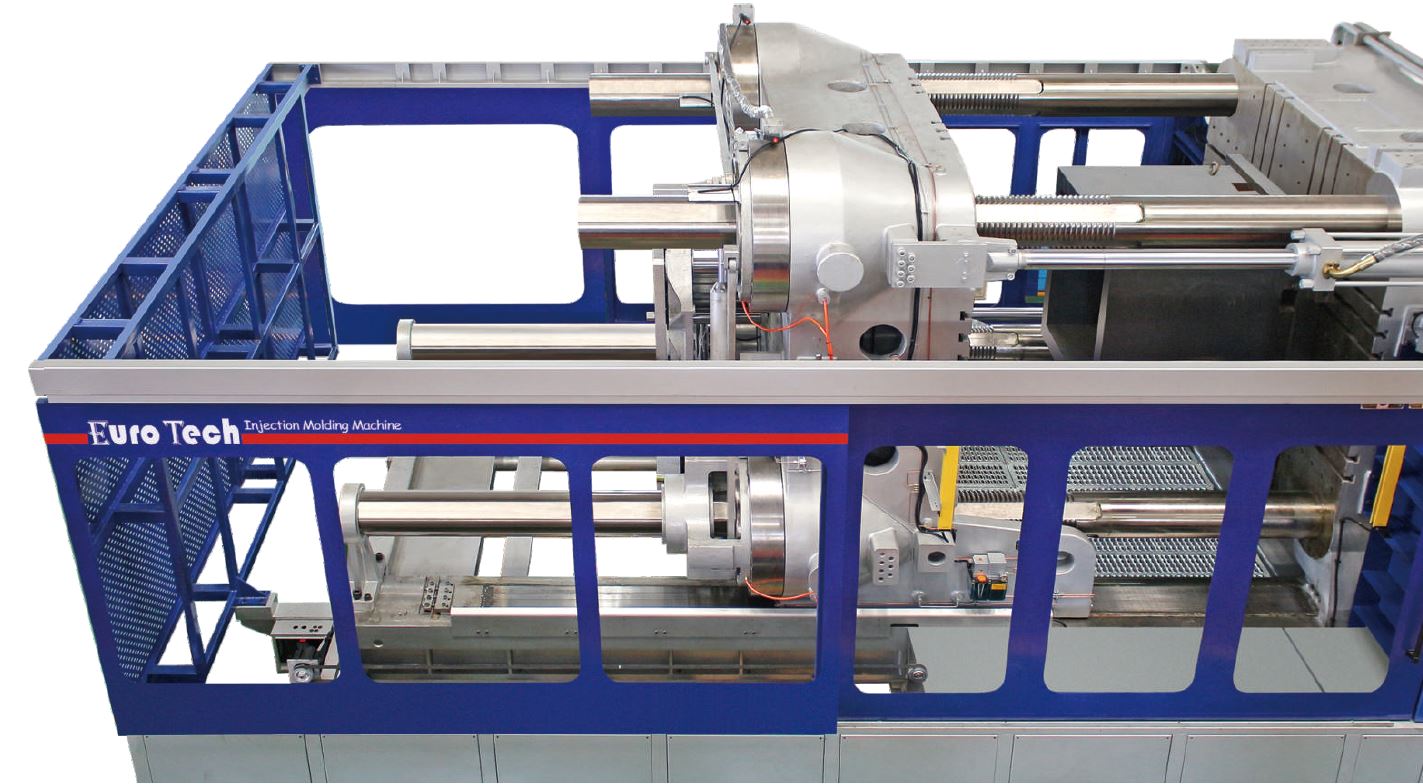

Improved cycle durations

Swift rotations – The key success factor of the model. Witness the synergy between the servo-electric clamping unit and hydraulic injection unit, incorporating advanced hydraulic accumulator technology.

Advanced two-platen clamp design for superior performance

The robust stiffness of the frame platen minimizes floor space requirements, while the interlocking mechanism ensures noiseless, seamless movements with exceptional precision and stability.

Enhanced Productivity and Energy Efficiency

Even with peak performance, expect lower energy demands: courtesy of the servo-electric direct drive for dosing and the efficient recovery of braking energy.

Cutting-edge control system

A precise and stable control system that complies with global injection standards along with multi-functional and specialized software and programming control.

Features

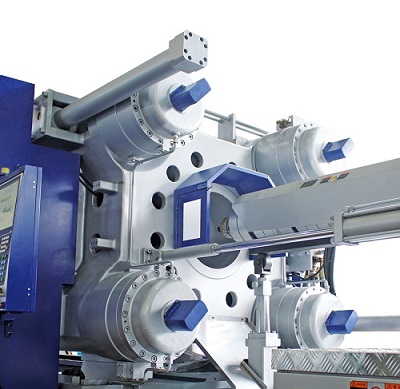

Injection Unit

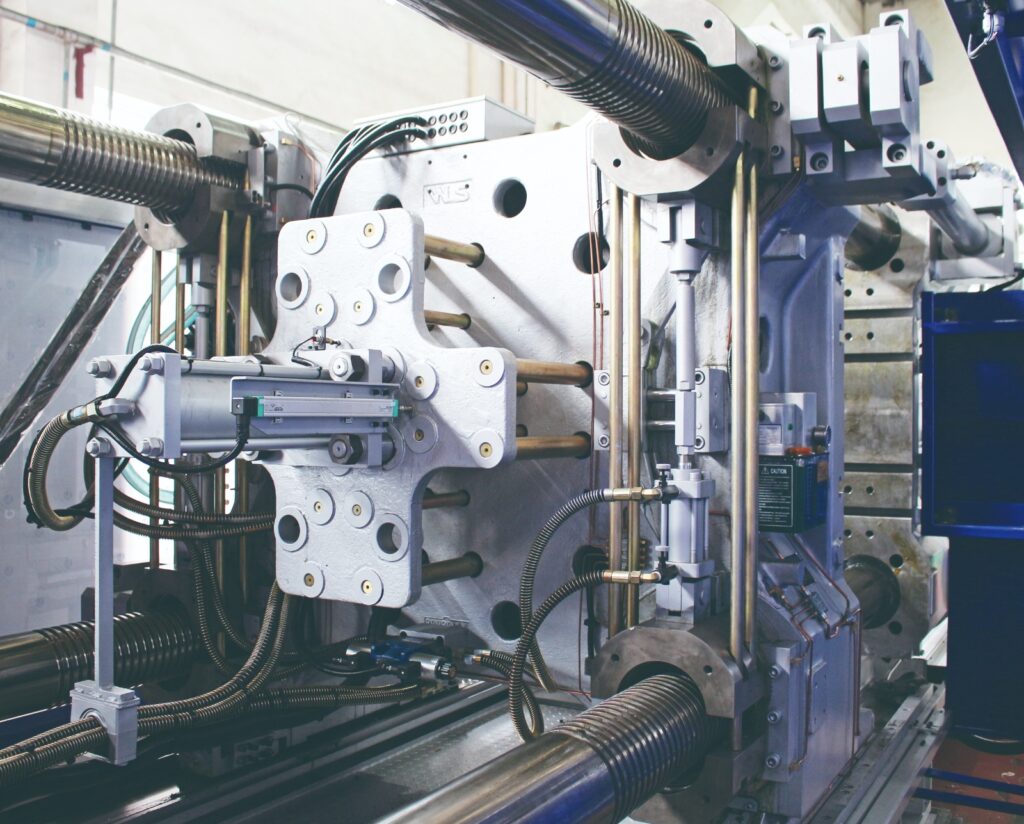

Clamping Unit

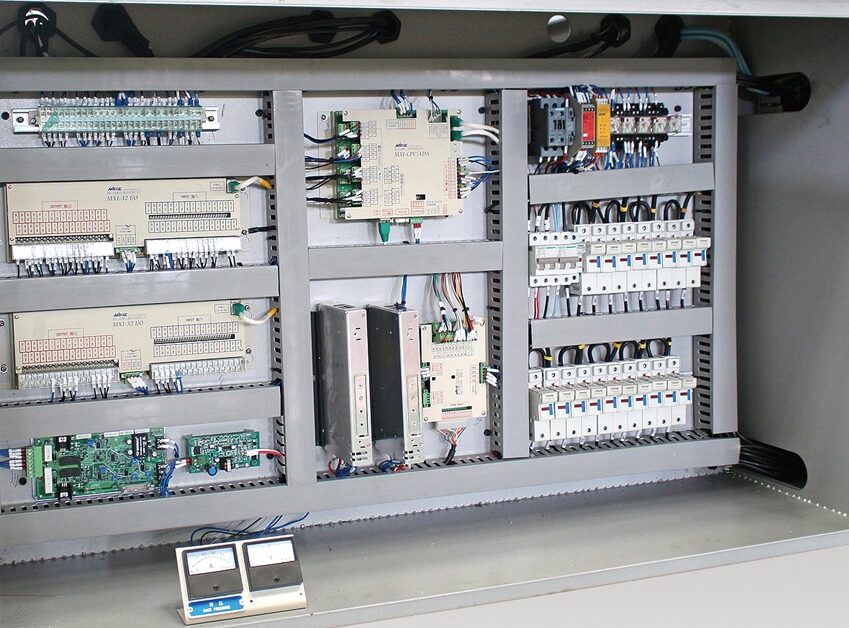

Controller Unit

Injection Unit

Eurotech Machine Injection Unit

- Screw sets of superior quality designed to accommodate considerably increased injection speeds.

- Tailored for processes demanding high speed and presenting challenges.

- Expanded equipment suitable for specialized and multi-component processes.

- Perfect function to adjust back pressure for stored materials.

- Safety-oriented nozzle guard equipped with an electrical interlock for operator protection.

- Reduced dry cycle times by up to 15 percent and Applicable across a diverse range of products.

Clamping Unit

GESTICA control system

Eurotech Machine Clamping Unit

- Featuring a robust frame platen with high stiffness, effectively reducing the required floor area.

- Opening stroke easily optimized based on product demand.

- Swift and stable mold opening and clamping, enhancing cycle time efficiency.

- Digital four-stage servo control for regulating pressure, speed, and the position of mold opening and closing.

- Automated centralized lubrication system coupled with a high-speed mold clamping function.

- Automatic mold adjustment with automatic lubrication of toggle bushings with grease.

- Ensuring safety with low-pressure mold protection, programmable ejector speed in two stages (hydraulic and electrical), and safety interlocks for gates.

Controller Unit

Control system

- A sizable color LCD screen, a protection lock for parameter resources, and the pre-setting of technical parameters for enhanced functionality.

- Incorporating an emergency stop protection function, live detection to display the operational status of each motion, and an abnormal functional alarm system for enhanced safety and monitoring.

- Visual representation of real-time graphics, including injection pressure, back pressure, and screw speed. Additionally, a digital display showcasing position, speed, pressure, temperature, servo information, motor speed, torque, and temperature.

- Comprehensive diagnostic function with an alarm help menu, storage of hourly production data for one year, and a multi-level password function for enhanced security.

Technical Data

EZ/1600 Ton

EZ/1600 Ton

| Distance between tie bar (mm) | 1100 X 960 | |||

|---|---|---|---|---|

| Clamping force (KN) | 7500 | |||

| Injection unit | A | B | C | D |

| Screw Diameter (mm) | 90 | 95 | 105 | 110 |

| Scre L/D ratio | 23.2 | 22 | 19.9 | 19 |

| Injection Weight (g) | 2807 | 3128 | 3821 | 4193 |

EZ/1300 Ton

EZ/1300 Ton

| Distance between tie bar (mm) | 1100 X 960 | |||

|---|---|---|---|---|

| Clamping force (KN) | 7500 | |||

| Injection unit | A | B | C | D |

| Screw Diameter (mm) | 90 | 95 | 105 | 110 |

| Scre L/D ratio | 23.2 | 22 | 19.9 | 19 |

| Injection Weight (g) | 2807 | 3128 | 3821 | 4193 |

EZ/1100 Ton

EZ/1100 Ton

| Distance between tie bar (mm) | 1100 X 960 | |||

|---|---|---|---|---|

| Clamping force (KN) | 7500 | |||

| Injection unit | A | B | C | D |

| Screw Diameter (mm) | 90 | 95 | 105 | 110 |

| Scre L/D ratio | 23.2 | 22 | 19.9 | 19 |

| Injection Weight (g) | 2807 | 3128 | 3821 | 4193 |

EZ/750 Ton

EZ/750 Ton

| Distance between tie bar (mm) | 1100 X 960 | |||

|---|---|---|---|---|

| Clamping force (KN) | 7500 | |||

| Injection unit | A | B | C | D |

| Screw Diameter (mm) | 90 | 95 | 105 | 110 |

| Scre L/D ratio | 23.2 | 22 | 19.9 | 19 |

| Injection Weight (g) | 2807 | 3128 | 3821 | 4193 |